- Tel: +86-15305875100

- E-mail: [email protected]

- Please contact us if you have questions.

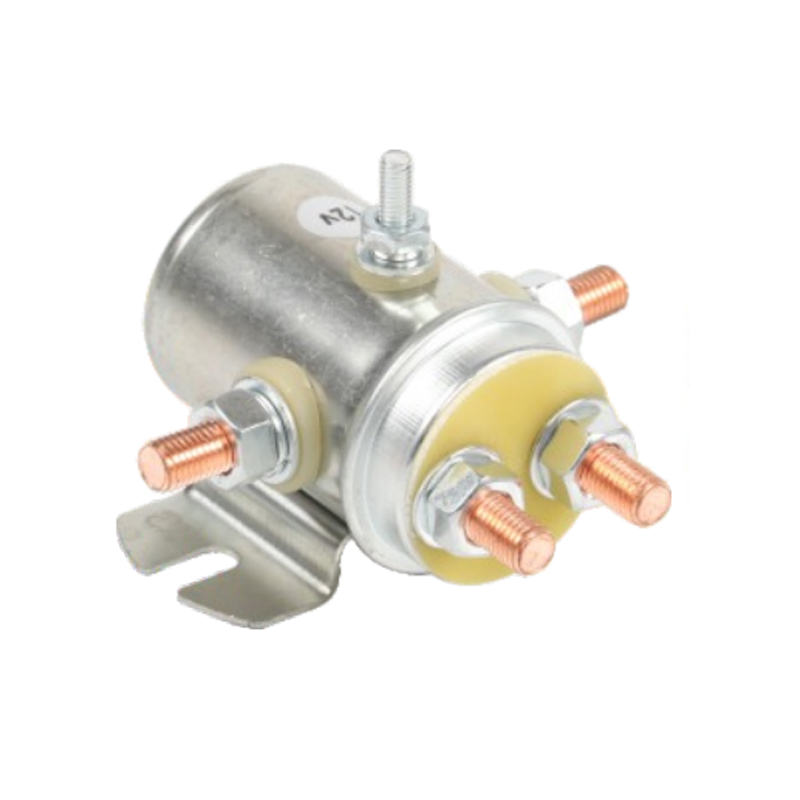

Understanding Whether Winch Relays Offer Built-In Short Circuit or Overload Protection Features

When operating a powered winch, ensuring safe and reliable performance under various conditions is paramount. One essential component in such a system is the Winch Relay, which acts as the intermediary switch between the power source and the winch motor. A key safety-related question for many users and equipment designers is whether a Winch Relay includes built-in protection features such as short-circuit or overload prevention. While some relays offer limited protection by design, full protection typically involves additional system-level components.

Basic switching role of the relay

The primary function of a Winch Relay is to control the high-current flow to the winch motor, enabling it to turn on or off based on user input. It is essentially a heavy-duty switch that responds to a control signal, usually from a wired or wireless remote. In many standard configurations, the relay itself does not actively detect or prevent electrical faults; it simply opens or closes the circuit when activated. This means that unless explicitly designed with safety electronics, the relay alone may not be capable of fully protecting against short circuits or overcurrent conditions.

Passive design limitations

Most traditional relays, including many used in winch systems, are electromechanical devices that lack intelligence. They do not have the sensors, logic, or feedback mechanisms needed to detect a fault in real time. If a short circuit occurs—due to a damaged wire, motor malfunction, or improper installation—the relay will continue to conduct current until it is manually shut off or another safety device intervenes. Similarly, in the case of an overload where the current exceeds safe limits, the relay’s internal contacts might overheat, weld together, or fail catastrophically if no additional protection is present.

Integrated relay-fuse units

In some cases, modern Winch Relay designs do integrate basic protection features. For example, relay-fuse combinations or relay units with built-in circuit breakers are available. These designs include thermal or magnetic components that can detect excessive current and automatically open the circuit, effectively protecting the rest of the system. However, these are typically specialized components and not standard across all winch relay models. Buyers looking for this functionality should carefully review product specifications to confirm whether such integrated protection is provided.

System-level protection is essential

Rather than relying solely on the relay, most well-designed winch systems include separate components for electrical protection. These may consist of inline fuses, manual reset breakers, or electronic overload protection modules installed between the battery and the relay or motor. These devices monitor current draw and disconnect the circuit automatically when dangerous levels are detected, protecting both the relay and the motor from damage. This layered approach enhances safety and allows easier identification of issues during troubleshooting.

Smart relay technologies

As winching systems become more sophisticated, so do the relays used to control them. Some advanced relays now include microcontroller-based monitoring, temperature sensors, and intelligent switching algorithms. These smart relays can detect overcurrent conditions and shut down the circuit without external intervention. However, they tend to be more expensive and are generally found in commercial or heavy-duty applications rather than standard consumer-level winches.

Conclusion

While the basic Winch Relay may not inherently include active short circuit or overload protection, modern systems can be designed with integrated safety components or paired with external protective devices. Understanding the specific model and its capabilities is crucial for ensuring safe operation. For users requiring fault detection and automated response, investing in a smart relay or incorporating fuses and circuit breakers into the winch system is a reliable approach.

News categories

Related Products

Request for a call today

-

-

Sophia Ye

-

Phone: +86-15305875100

-

WhatsApp: 15305875100

-

Email: [email protected]

-

- Mobile Terminal

English

English Español

Español